Sugar Drying Equipment

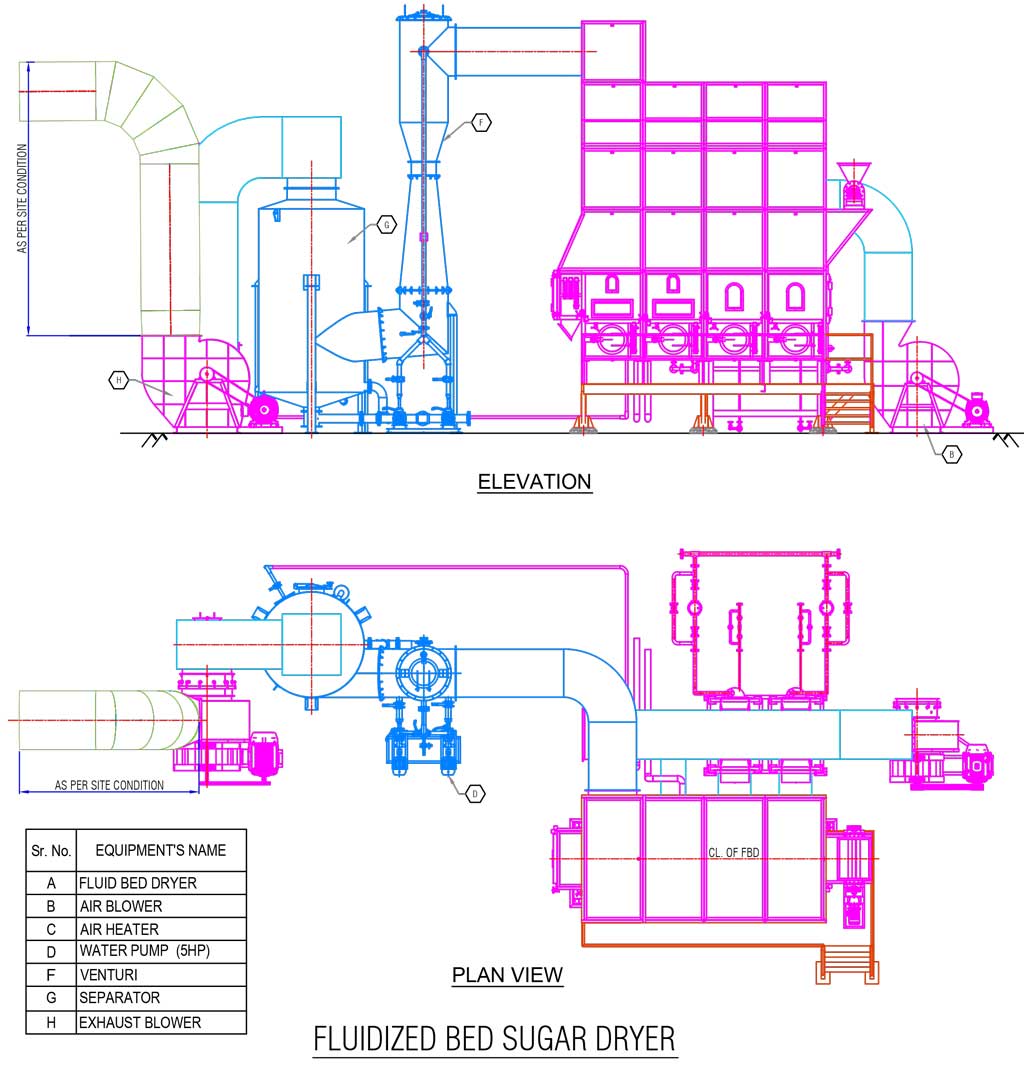

Fluidized Bed Dryer

Fluid bed dryer are found throughout all industries, from heavy mining to food, fine chemicals and Pharmaceuticals and sugar industry. It is stationary equipment, provided with FD and ID pans, with various capacities from 15T/hr to 50T/hr along with dust catching system. They provide an effective method of drying relatively free flowing particles with a reasonably narrow particle size distribution. In general, fluid bed dryers operate on a through-the-bed flow pattern with the hot air passing through the product perpendicular to the direction of travel. The dry product is discharged from the same section.

Advantages of FBD:

- High rate of heat transfer is achieved with almost instant evaporation.

- Batch/continuous flow material is possible.

- Moisture reduction from l.5% to 0.02-0.03%.

- In fluid bed drying, the heat and mass transfer rates are faster by a magnitude of one.

- Sugar temperature should be close to wet bulb temperature of air. This allows gentle drying without caramelisation of sugar.

- The gentle drying and cooling process brings with it an excellent product quality, especially with regards to brightness of the product.

- The enlarged cross-section above the fluid bed reduces dust discharge.

- Stationary type / No hopper movement reduces crystal breakage.

- Lower maintenance due to absence of moving parts.

More than 55 units supplied to India, Kenya, Uganda, Thailand, Vietnam, Indonesia, Ethiopia, Laos & China.

Rotary Sugar Dryers

Rotary Dryers represent the oldest continuous and undoubtedly the most common high volume dryer in industry and it has evolved more adaptations of the technology than any other dryer classification.

With the rotary movement of the Dryer, solids are picked up by the specially designed flights to a certain distance around the drum and showered through the air in a cascading curtain. Most of the drying occurs at this time, as the solid are in close contact with the hot air. Flight action is also partly responsible for the movement of solids through the drum.

Advantages of Rotary Dryers:

- Reduced crystal damage and dust formation due to very shortfall.

- Low space requirement to achieve both drying and cooling.

- The use of counter current drying and cooling in a single unit.

- Low drive power consumption due to the balanced load of the product around the axis of rotation.

- Lower maintenance cost due to fewer items of ancillary equipment.

- Moisture reduction from 1.5 % to 0.02-0.03 %

- Dust free environment and avoids the material loss due to no dust emission.

More than 50 units supplied to India, Kenya, Uganda, Thailand, Vietnam, Indonesia, Algeria & Peru.

View brochure - Shrijee Fluidized Bed Sugar Dryer

View brochure - Shrijee Fluidized Bed Sugar Dryer