Molasses Cooling System

Introduction:

Shrijee has developed, manufactured and supplied the Molasses Cooler for cooling of B Heavy Molasses or Final Molasses, and also for Syrup cooling. To produce ethanol from B Heavy or Final Molasses, cooling of molasses becomes necessary before sending to storage.

Aim of Molasses Cooling:

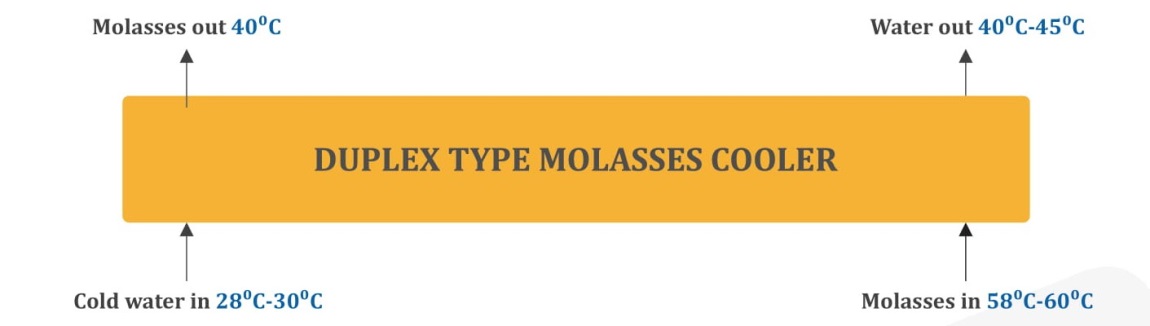

To maintain proper conditions for storage of molasses i.e. both qualitative and quantitative losses are to be avoided. As from commercial angle molasses storage has vital importance in view of its revenue earning potential. The effect of non-sucrose in the process is therefore an important factor in determining the quantity of molasses and hence the amount of sugar lost in molasses. The conversion of this fermentable reducing sugars to non-fermentable reducing o o sugars (NFRS) increases with rise in temperature of storage. At 38 C – 40 C, the increase in this loss of fermentable o reducing sugar per year is 2% to 3%. A rise of 10 C is reported to have quadrupled the decomposition. Most rapid o decomposition occurs at temp above 40 C with the increase in nitrogen content in juice i.e. with the increase in amino acids and amides etc

Process of Cooling the Molasses:

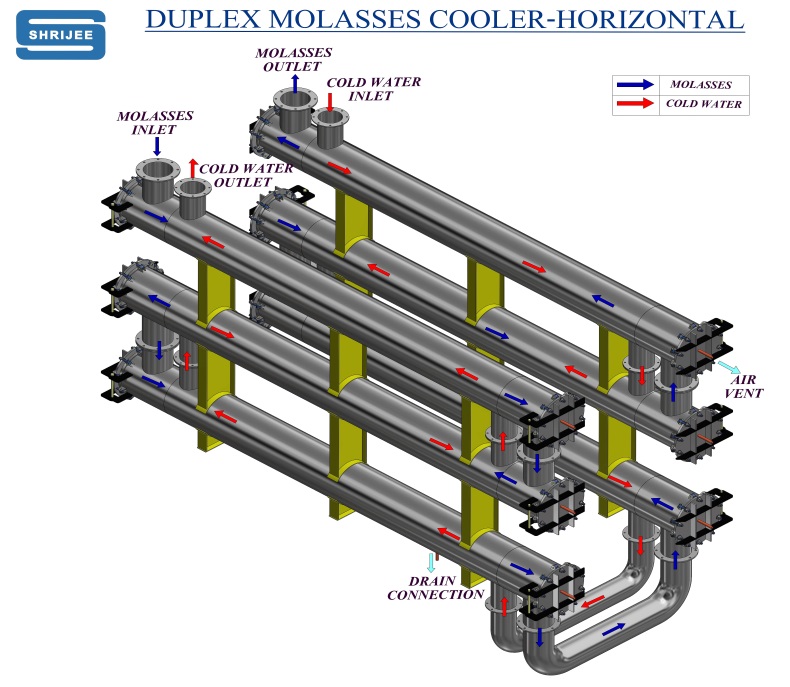

Tubular molasses coolers will have more number of tiny coolers with single pass for molasses and cooling water. Molasses will pass through the tubes whereas cooling water shall pass outside of the tubes. The cooling water and molasses will travel in counter current direction and required cooling can be achieved. The required outlet temperature will depend upon the cooling surface area of molasses cooler.

Features:

- Duplex type Molasses Cooler

- Liquid to Liquid

- Horizontal/Vertical installation

- Tiny coolers with cover & multi bolt system

- Easy to clean

- Low maintenance & highly efficient

- Minimum head loss

- Direct installation without disturbing existing arrangement

- Long Life

- Shrijee’s molasses cooler can be installed in the recirculation line for molasses storage tank

Parameters Required:

- Type of molasses- B Heavy, final or syrup

- Brix of the Molasses

- Inlet & Outlet temperature of molasses

- Quantity of molasses

- Temperature of water to be used for cooling

View brochure - Shrijee Molasses Cooling System

View brochure - Shrijee Molasses Cooling System